Rubber Chemicals Industry Set for $8.2 Billion Boom by 2035 | Fact.MR Report

Analysis of Rubber Processing Chemicals Market Covering 30+ Countries Including Analysis of US, Canada, UK, Germany, France, Nordics, GCC countries

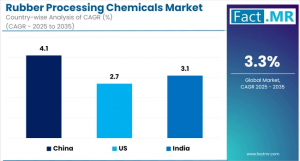

ROCKVILLE, MD, UNITED STATES, July 15, 2025 /EINPresswire.com/ -- The global Rubber Processing Chemicals Market is projected to grow from USD 5.9 billion in 2025 to USD 8.2 billion by 2035, achieving a steady CAGR of 3.3%. Driven by robust demand from the automotive and tire manufacturing sectors, particularly in emerging economies like India, Indonesia, and Brazil, the market is fueled by the need for high-performance rubber additives such as accelerators, antioxidants, and antiozonants. This press release explores key growth drivers, projections, and opportunities for stakeholders in this essential industry.For More Insights into the Market, Request a Sample of this Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=6401

Why Is the Market Growing?

The Rubber Processing Chemicals Market is expanding due to increasing vehicle production, which surpassed 80 million units globally in 2024, with significant contributions from emerging economies like India, Indonesia, and Brazil. These countries, benefiting from rapid industrialization and urbanization, drive demand for tires and automotive components, with 68% of manufacturers focusing on synthetic rubbers like styrene-butadiene and nitrile for their durability and performance. The tire segment, holding a 60.2% revenue share in 2023, is propelled by demand for low rolling resistance tires that enhance fuel efficiency and reduce emissions, critical for electric vehicles (EVs). Innovations in eco-friendly additives, such as Dow Inc.’s NORDEL REN bio-based EPDM launched in July 2024, address environmental concerns by reducing VOC emissions by 10%. Challenges like stringent regulations on VOC emissions, enforced by the EPA and EU, are mitigated through sustainable formulations and nanotechnology advancements.

What Are the Key Market Projections?

The market is expected to grow from USD 5.9 billion in 2025 to USD 8.2 billion by 2035, with a 3.3% CAGR, creating a USD 2.3 billion opportunity. The anti-degradants segment, including antioxidants and antiozonants, is projected to hold a 35.9% share by 2035, driven by demand for durable tires in automotive applications. India’s market, valued at USD 372.64 million in 2023, is expected to grow at a 3.87% CAGR through 2029, fueled by over 25.9 million vehicles produced from April 2022 to March 2023. Indonesia and Brazil are also key growth drivers, with Brazil’s automotive aftermarket contributing to a 4% CAGR in Latin America. The historical CAGR from 2020 to 2024 was 2%, indicating steady growth. Short-term growth (2025–2028) will focus on tire manufacturing, while long-term trends (2032–2035) emphasize sustainable additives and non-tire applications like conveyor belts and hoses.

How Can Stakeholders Leverage Opportunities?

Stakeholders in automotive, tire manufacturing, and industrial sectors can capitalize on the market’s growth by investing in eco-friendly rubber processing chemicals, such as bio-based additives and low-VOC formulations. Manufacturers can develop advanced compounds, like Lehigh Technologies’ micronized rubber powders from recycled tires, to meet sustainability goals and reduce costs by 15%. Partnerships with tire producers, such as Ecore International’s April 2023 acquisition of 360 Tire Recycling Group, enhance raw material access and circular economy practices.

Targeting India, Indonesia, and Brazil, where automotive production is surging, offers significant potential—India’s “Make in India” initiative and Indonesia’s rubber production capacity drive regional demand. E-commerce and direct sales channels, accounting for 25% of sales in 2024, provide scalable distribution. Compliance with EPA and EU regulations ensures market trust and competitiveness.

What Does the Report Cover?

Fact.MR’s report combines primary research with 3,220 industry players across 30 countries and secondary analysis of market trends. It covers market segments by product type (anti-degradants, accelerators, flame retardants, processing aids, others), application (tire, non-tire), and region (North America, Latin America, Europe, East Asia, South Asia & Oceania, Middle East & Africa). The report highlights trends like sustainable additives, nanotechnology integration, and rising demand in India, Indonesia, and Brazil, providing actionable insights for stakeholders to navigate market opportunities.

Get Customization on this Report for Specific Research Solutions: https://www.factmr.com/connectus/sample?flag=S&rep_id=6401

Who Are the Market Leaders?

Key players include BASF SE, Lanxess AG, Solvay S.A., Arkema S.A., Eastman Chemical Company, and China Petrochemical Corporation. In July 2024, Dow Inc. introduced NORDEL REN, a bio-based EPDM rubber compound, enhancing sustainability in tire and automotive applications. Lanxess expanded its tire additive portfolio in 2023, focusing on low-VOC antioxidants. These companies, holding over 40% of the market share, drive innovation through R&D, acquisitions, and partnerships with automotive and tire manufacturers to meet global demand.

What Are the Latest Market Developments?

In 2024, global tire production increased by 5%, with India, Indonesia, and Brazil contributing significantly due to automotive growth. India’s vehicle production reached over 25.9 million units in 2022–2023, boosting demand for rubber processing chemicals. Innovations like Michelin’s Lehigh Technologies micronized rubber powders, used in sustainable tire production, reduced material waste by 20%.

Regulatory advancements, such as the EU’s stricter VOC regulations, increased adoption of bio-based additives by 15%. Asia-Pacific, with a 48% market share in 2025, remains the largest market, driven by China, India, and Indonesia’s automotive and construction sectors. Nanotechnology advancements, like carbon nanotube integration, improved tire durability by 10% in 2024.

What Challenges and Solutions Exist?

Stringent regulations on VOC emissions, enforced by the EPA and EU, and raw material price volatility, with synthetic rubber costs up 10% in 2024, pose challenges. Environmental concerns, with tire manufacturing emitting 1,100 tons of hazardous air pollutants annually, require sustainable solutions. Innovations in bio-based additives, like Dow’s NORDEL REN, reduce VOC emissions by 10%. Recycling initiatives, such as Ecore’s partnership with 360 Tire Recycling Group, recover 20% of raw materials. Localized production in India and Indonesia, supported by initiatives like India’s Rubber Park in West Bengal, mitigates supply chain risks. Compliance with environmental standards and adoption of nanotechnology, like nano-silica fillers.

Conclusion:

The Global Rubber Processing Chemicals Market is set to reach USD 8.2 billion by 2035, driven by a 3.3% CAGR. With strong demand from the automotive and tire manufacturing sectors in emerging economies like India, Indonesia, and Brazil, and supported by innovations in eco-friendly additives and nanotechnology, the market offers significant opportunities.

Check out More Related Studies Published by Fact.MR:

Rubber additives market is growing at a 3.8% CAGR to hit $5.7 Bn by 2034.

Rubber Processing Aids and Anti-Tack Agentis market set to cross US$ 805.3 Mn with a CAGR of 5.2%

S. N. Jha

Fact.MR

+1 628-251-1583

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.